Trusted by container shipping

Silverstream’s technology is trusted by leading container ship owners – reflecting the strong technical fit and commercial confidence in our solution for this vessel type. With high speeds, large flat bottoms, and frequent long-haul voyages, container ships are ideal candidates for the Silverstream® System. Our proven solution helps operators improve CII ratings, reduce emissions costs, and maintain a competitive edge in a rapidly evolving regulatory landscape.

Driving box market efficiency

Our technology has earned the trust of industry leaders such as Maersk and Mediterranean Shipping Company (MSC), reinforcing our position as the preferred partner for air lubrication in container shipping.

In 2021, MSC placed the largest-ever order for a maritime clean propulsion technology with over 30 vessels. It has since expanded its commitment to 84 systems from Silverstream, including for the world’s largest container ship, MSC Irina.

Container ships are particularly well-suited to Silverstream’s air lubrication system due to their large flat bottoms, high operating speeds, and long-distance trading patterns. Our system helps operators reduce fuel consumption and emissions, improving CII ratings and lowering exposure to emissions-related costs such as the EU ETS.

It provides customers with operational flexibility. Depending on their priorities, operators can choose to travel at higher speeds for the same fuel consumption, or cut fuel consumption and emissions without sacrificing speed.

Unlock the benefits of the Silverstream® System

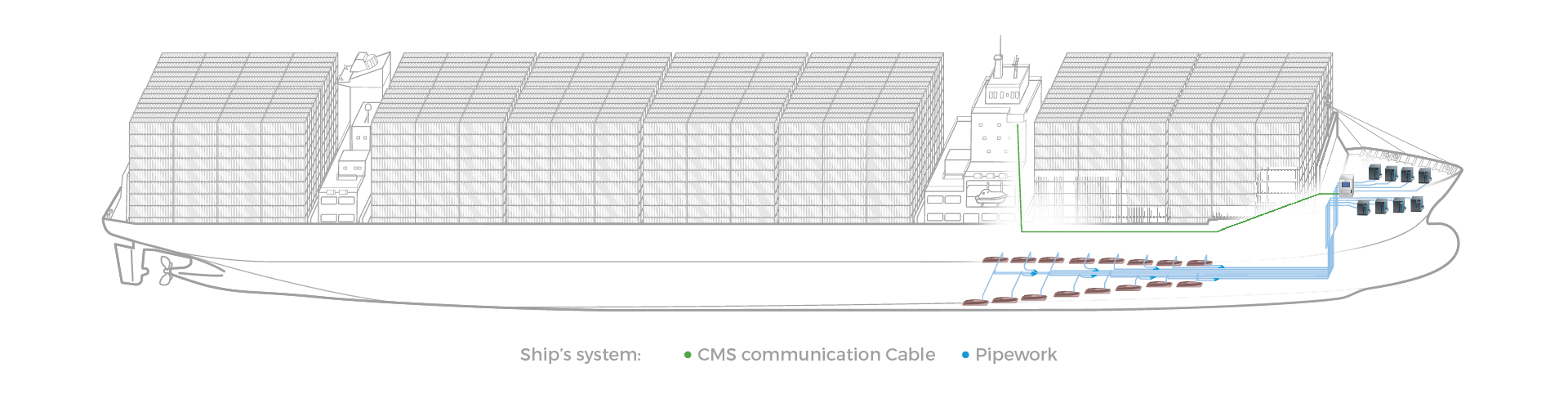

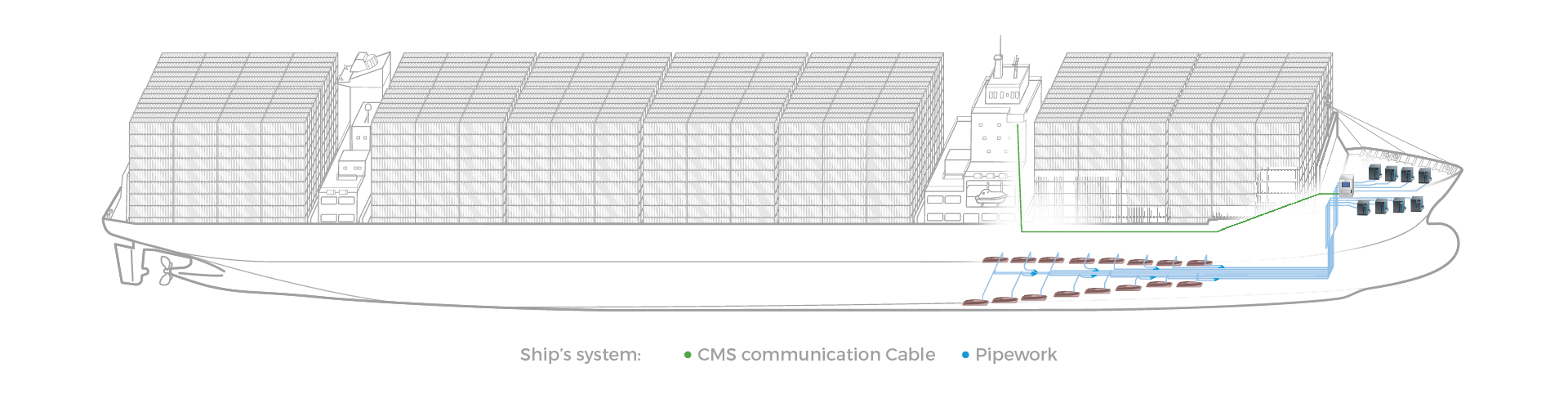

Our patented and fuel-agnostic Silverstream® System creates a uniform carpet of microbubbles that cuts frictional resistance between a ship’s hull and the water. This dramatically reduces fuel consumption and associated emissions, delivering between 5-10% proven net fuel and emissions savings, depending on vessel type. Our savings have been verified by independent third parties, including Lloyd’s Register, HSVA, the University of Southampton, Carnival and Shell.

Control and Monitoring System

Control and Monitoring System

Air Compressors

Air Compressors

Air Release Units

Air Release Units

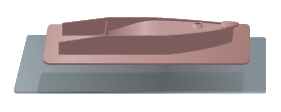

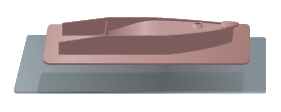

Air Balancing Module

Air Balancing Module

The air balancing module is a custom fabricated galvanised steel component for the Silverstream® System that distributes air from the compressor to both ARU branches. Flanged bosses are welded for the drain valve, level sensor and spares that are blanked to allow for troubleshooting.

Explore some of our latest container projects

Explore our installations across key vessel segments and see how the Silverstream® System could benefit your fleet.