Making net-zero shipping a reality

Market-leading air lubrication technology.

Empowered by air.

200 +

Vessels

5 bn

Fuel dollar savings

20 m

Tonnes of Co2

2 bn

Carbon tax dollars

At Silverstream, we aim high.

Shipping industry’s decarbonisation ambitions can be advanced with action today. By deploying and scaling our proven air lubrication technology, we strive to transform maritime energy efficiency. We help shipping cut fuel use, emissions, and costs – delivering real savings and driving performance. As the industry moves towards net-zero, we partner with leading owners, charterers, and shipyards to deliver lasting impact — empowered by air.

Unlock the benefits of the Silverstream® System

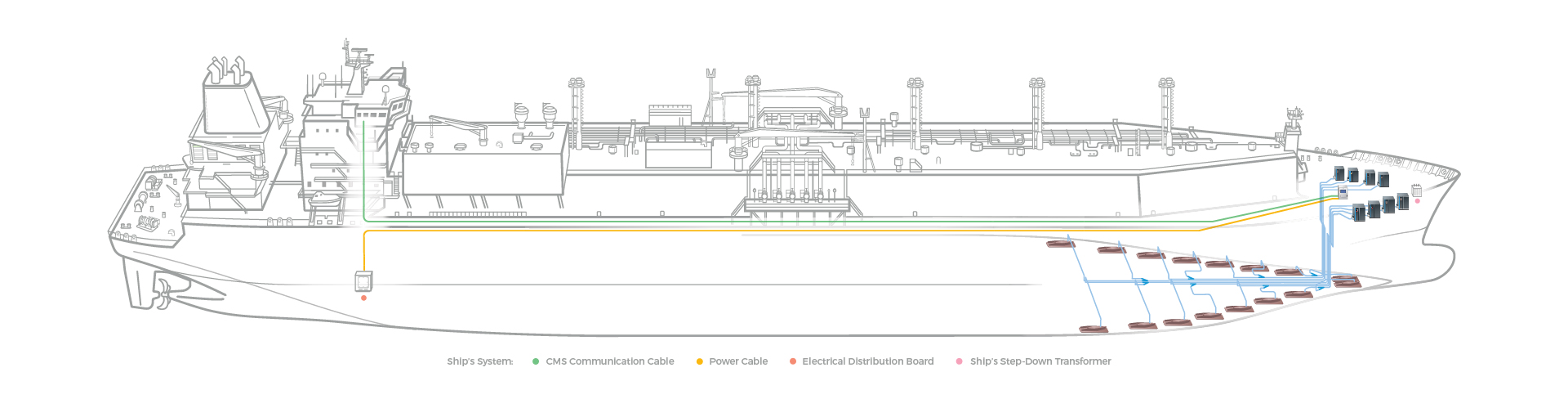

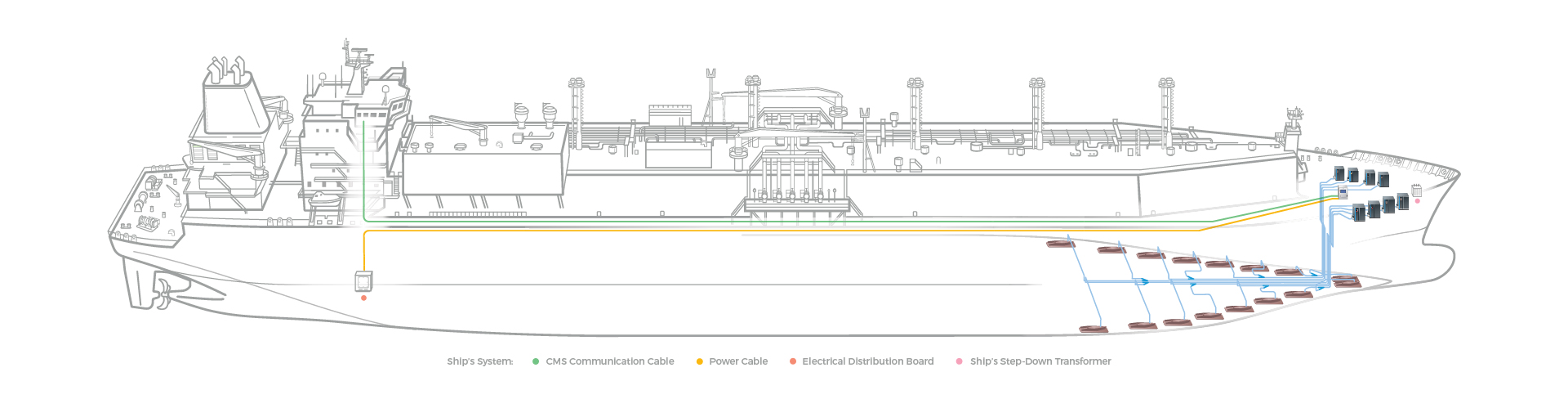

Our patented and fuel-agnostic Silverstream® System creates a uniform carpet of microbubbles that cuts frictional resistance between a ship’s hull and the water. This dramatically reduces fuel consumption and associated emissions, delivering between 5-10% proven net fuel and emissions savings, depending on vessel type. Our savings have been verified by independent third parties, including classification societies, academic institutions and shipping industry leaders.

Control and Monitoring System

Control and Monitoring System

Air Compressors

Air Compressors

Air Release Units

Air Release Units

Air Balancing Module

Air Balancing Module

The air balancing module is a custom fabricated galvanised steel component for the Silverstream® System that distributes air from the compressor to both ARU branches. Flanged bosses are welded for the drain valve, level sensor and spares that are blanked to allow for troubleshooting.

Work with the leader in air lubrication

Since 2010, Silverstream has been harnessing the power of air to drive decarbonisation in shipping, creating the market for air lubrication.

Today, we are a global multi-award-winning business leading the way with the largest installed base of air lubrication systems. We work with industry-leading shipyards as well as owners and charterers across all major shipping segments, setting the standard for energy savings, safety, and quality.

Newbuilds

The Silverstream® System is simple to operate, and is easy to install on newbuilds. Our goal is to make air lubrication a global standard for all newbuild vessels.

Retrofits

Our retrofitting projects can typically be completed in 10 days during planned dry dock periods, with the fastest recorded dry dock installation being 6 days.

Aftercare

Silverstream® Service helps customers unlock the full value of their Silverstream® System over its lifetime. We provide tailored aftercare solutions to meet individual needs, ensuring reliable uptime and long-term performance.

Decarbonisation and regulatory compliance

The Silverstream® System supports compliance with key regulations such as EEDI, EEXI, CII, FUEL EU Maritime and the EU ETS.

We help our customers navigate an evolving regulatory landscape, delivering real emissions savings and future-proofing their fleet.

- EEDI

- EEXI

- CII

- FUEL EU Maritime

- EU ETS

Trusted by our industry-leading partners

Global reach

With a global footprint and strong partnerships across the maritime industry, our technology is trusted by leading shipowners and operators, and we work closely with 20 major shipyards worldwide to deliver installations at scale.

Find us at our headquarters in London, our offices in Southampton and Shanghai, and at the many global maritime hubs where our projects are delivered.

- Silverstream offices

- Partner Shipyards