Driving efficiency across RoRo and PCTC fleets

Roll-on/roll-off vessels (RoRo) and Pure Car and Truck Carriers (PCTC) are an important focus for Silverstream and a growing part of our portfolio. Our longstanding partnership with Grimaldi Group is testament to the effectiveness of the Silverstream® System in reducing fuel consumption and emissions in real-world operations.

Proven performance and long-term partnerships in RoRo and PCTC

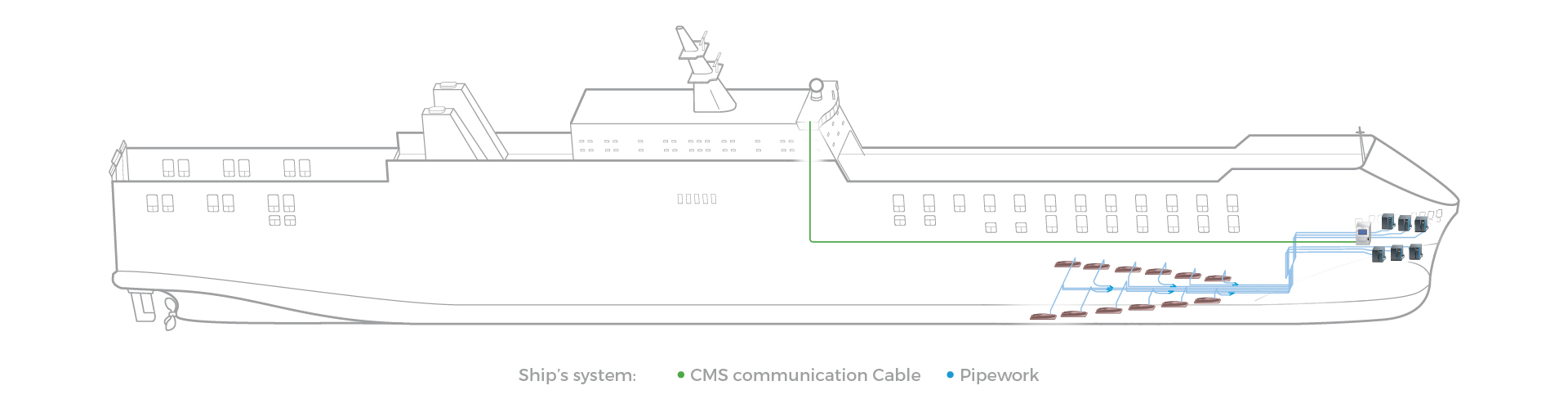

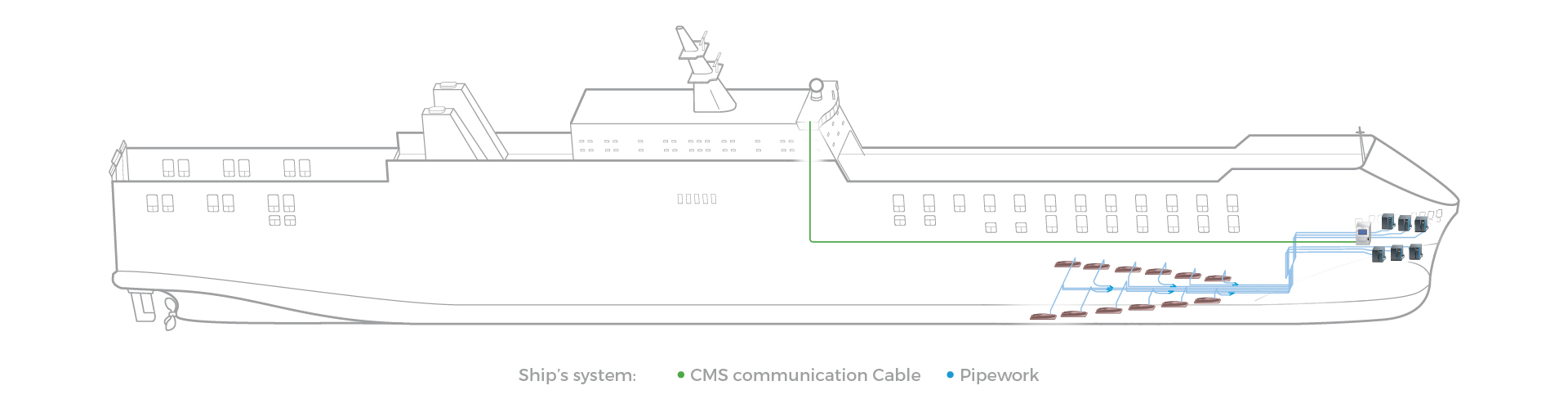

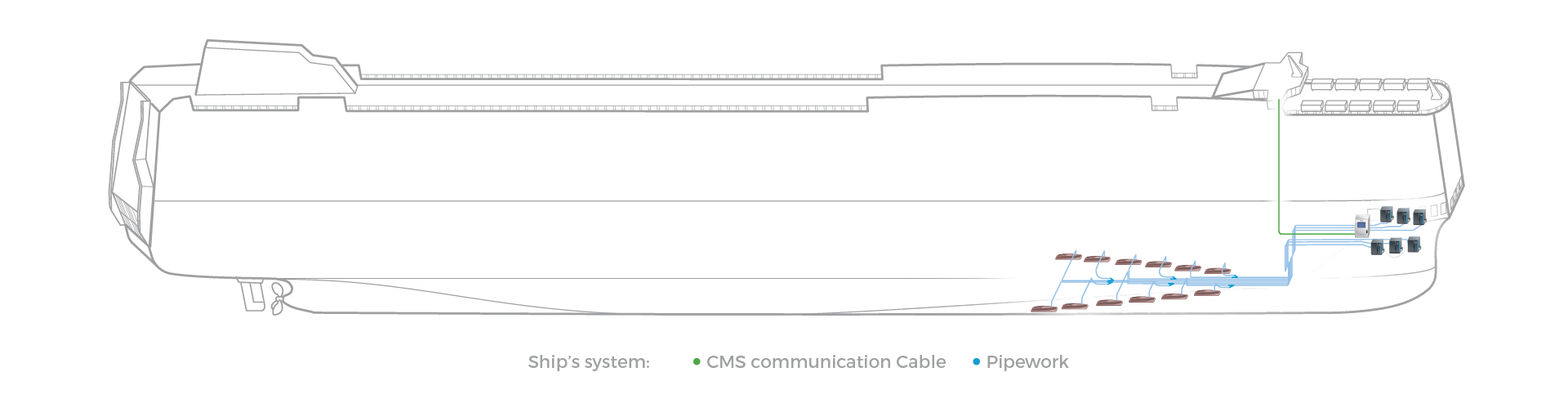

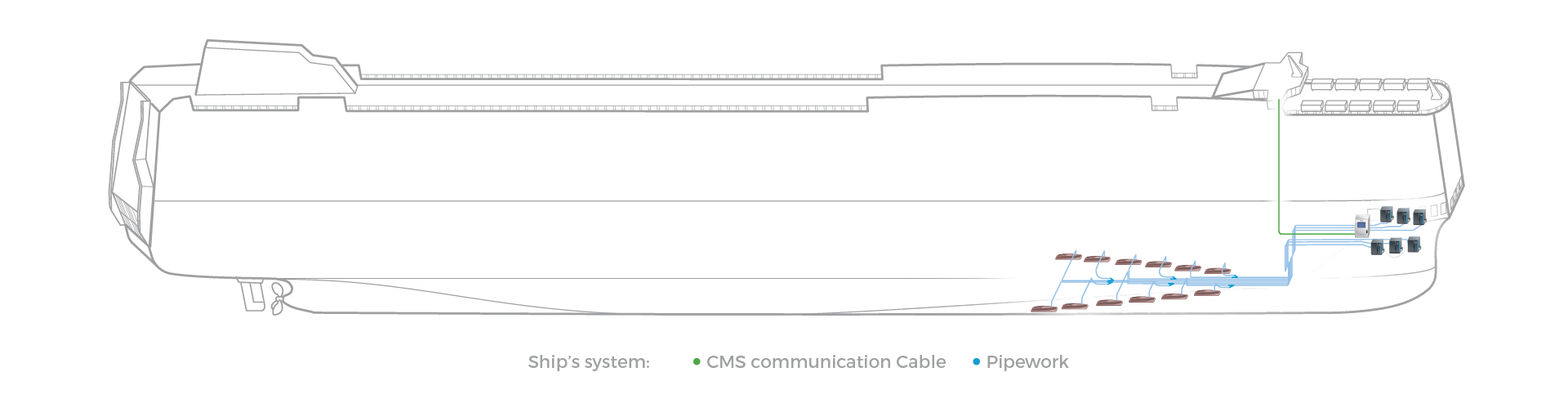

RoRo and PCTC vessels are well-suited to benefit from air lubrication. Their relatively flat-bottomed hull forms offer an ideal surface for a uniform layer of microbubbles, reducing frictional resistance and improving overall vessel efficiency. We also offer a tailored solution for PCTCs to ensure an optimal fit for our air release units. Operating on regular schedules with frequent port calls and varying speeds, these vessels are ideal candidates for the Silverstream® System’s proven performance across a wide range of operational profiles.

Our collaboration with Grimaldi began in 2018 and has grown to include 16 operational vessels and 10 more in progress. For Grimaldi’s GG5G-class RoRo vessels, we have delivered proven net fuel and emissions savings of 5–6%, contributing meaningfully to their sustainability goals.

The system also supports compliance with key environmental regulations. It helps operators meet Energy Efficiency Design Index (EEDI) and Energy Efficiency Existing Ship Index (EEXI) requirements for both newbuilds and retrofits, while also improving Carbon Intensity Index (CII) ratings – increasingly important for long-term fleet performance and, for PCTCs, charter competitiveness.

Unlock the benefits of the Silverstream® System

Our patented and fuel-agnostic Silverstream® System creates a uniform carpet of microbubbles that cuts frictional resistance between a ship’s hull and the water. This dramatically reduces fuel consumption and associated emissions, delivering between 5-10% proven net fuel and emissions savings, depending on vessel type. Our savings have been verified by independent third parties, including Lloyd’s Register, HSVA, the University of Southampton, Carnival and Shell.

Control and Monitoring System

Control and Monitoring System

Air Compressors

Air Compressors

Air Release Units

Air Release Units

Air Balancing Module

Air Balancing Module

The air balancing module is a custom fabricated galvanised steel component for the Silverstream® System that distributes air from the compressor to both ARU branches. Flanged bosses are welded for the drain valve, level sensor and spares that are blanked to allow for troubleshooting.

Control and Monitoring System

Control and Monitoring System

Air Compressors

Air Compressors

Air Release Units

Air Release Units

Air Balancing Module

Air Balancing Module

The air balancing module is a custom fabricated galvanised steel component for the Silverstream® System that distributes air from the compressor to both ARU branches. Flanged bosses are welded for the drain valve, level sensor and spares that are blanked to allow for troubleshooting.

Explore some of our key RoRo and PCTC projects

Explore our installations across key vessel segments and see how the Silverstream® System could benefit your fleet.

Speak to our expert for RoRo & PCTC

Find out more about our latest RoRo and PCTC projects