Efficiency across an evolving gas fleet

As the global gas fleet evolves to meet rising demand and decarbonisation goals, operators across vessel types are under pressure to improve efficiency and reduce emissions. From LNG carriers crucial for the energy transition to next-generation CO₂ vessels designed for a net-zero future, the Silverstream® System is a natural fit. Our technology supports ship owners and charterers in meeting commercial and regulatory expectations – today and tomorrow.

Our Gas Customers

Why the Silverstream® System is the right fit for gas

The gas carrier segment – led by LNG – is evolving rapidly, driven by rising demand and tightening environmental regulations. As pressure grows to cut emissions and improve efficiency, our air lubrication system offers gas operators a proven solution.

The Silverstream® System is well suited to a wide range of gas carriers. Many LNG and LPG vessels operate with shallow draughts and high speeds, and feature large flat bottoms – conditions that enhance the performance of our system. Emerging segments like CO₂ carriers with optimised hull designs are being developed with efficiency and emissions reduction in mind, making them ideal candidates for our technology.

Regardless of the cargo transported, our system delivers significant fuel and emissions savings. It also enhances operational flexibility, enabling vessels to maintain speed while reducing consumption, or increase speed without burning more fuel.

We have delivered more retrofit projects for gas carriers than for any other segment, working closely with leading shipyards including Seatrium, Hudong-Zhonghua, and Yiu Lian to ensure minimal downtime and fast realisation of benefits.

We are also proud to be part of an industry milestone – the installation of the Silverstream® System on the Northern Lights CO₂ carriers, Northern Pioneer and Northern Pathfinder. These vessels are the world’s first purpose-built CO₂ carriers, and the first to feature an air lubrication system on an EEDI certificate. DNV validated 5% net savings and established a protocol for measuring the impact of air lubrication on EEDI.

Unlock the benefits of the Silverstream® System

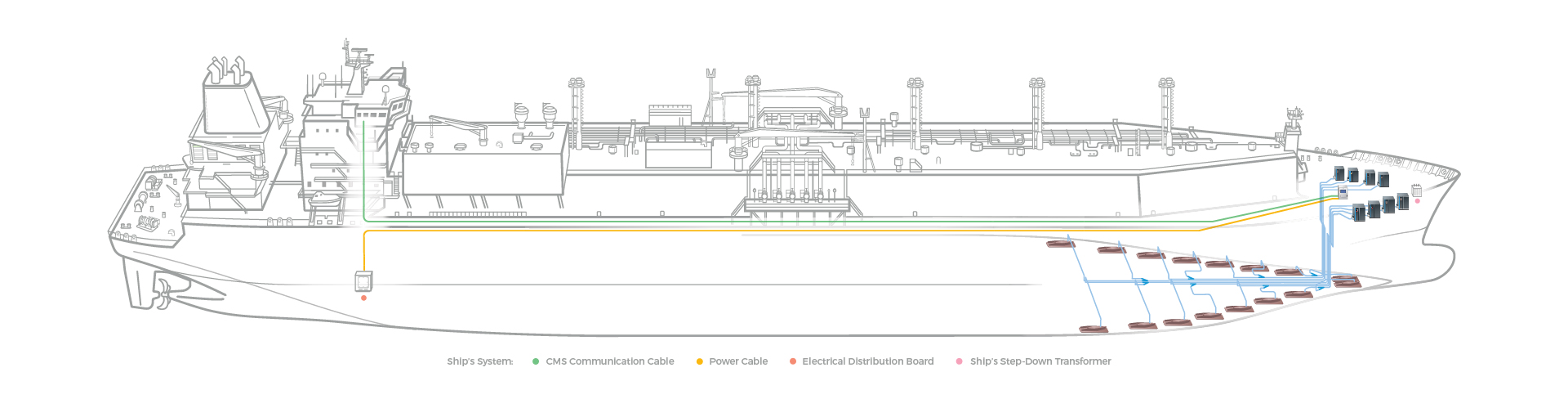

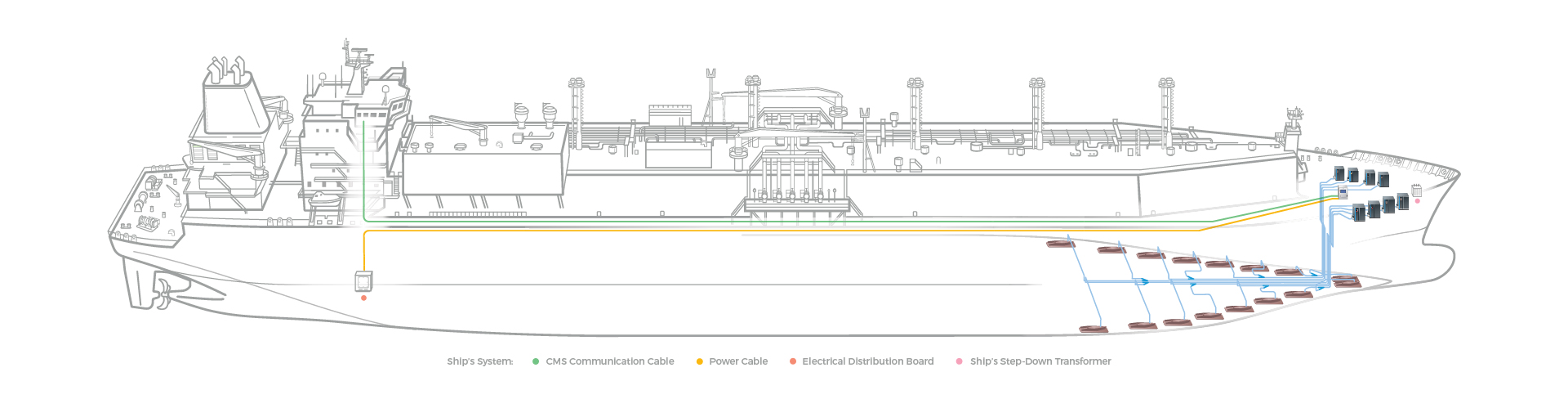

Our patented and fuel-agnostic Silverstream® System creates a uniform carpet of microbubbles that cuts frictional resistance between a ship’s hull and the water. This dramatically reduces fuel consumption and associated emissions, delivering between 5-10% proven net fuel and emissions savings, depending on vessel type. Our savings have been verified by independent third parties, including classification societies, academic institutions and shipping industry leaders.

Control and Monitoring System

Control and Monitoring System

Air Compressors

Air Compressors

Air Release Units

Air Release Units

Air Balancing Module

Air Balancing Module

The air balancing module is a custom fabricated galvanised steel component for the Silverstream® System that distributes air from the compressor to both ARU branches. Flanged bosses are welded for the drain valve, level sensor and spares that are blanked to allow for troubleshooting.

Explore some of our key gas projects

Explore our installations across key vessel segments and see how the Silverstream® System could benefit your fleet.