Partnering with cruise industry for cleaner, more efficient voyages

The cruise sector faces increasing pressure to meet ambitious decarbonisation targets while maintaining exceptional passenger experiences. Our air lubrication technology is uniquely positioned to support cruise operators in reducing fuel use and emissions, while helping mitigate underwater radiated noise (URN), a growing environmental concern.

Proven performance fuelling cruise decarbonisation

Silverstream’s air lubrication technology is a strong match for the cruise industry – delivering proven emissions and fuel savings while supporting operators’ broader environmental goals. Since 2016, we’ve worked closely with Carnival, the world’s largest cruise operator, accelerating progress on fleet decarbonisation.

With 5% proven net fuel and emissions savings onboard Diamond Princess, we are scaling our performance across a growing number of vessels. More than 20 systems are either installed or on order, supporting the rollout of some of the most energy-efficient cruise ships in operation – and helping to shape a more sustainable future for the industry.

In a sector facing significant regulatory and public pressure, we offer a proven, scalable solution. Our technology also helps mitigate underwater radiated noise (URN), a growing priority for cruise operators committed to reducing their impact on marine ecosystems.

Unlock the benefits of the Silverstream® System

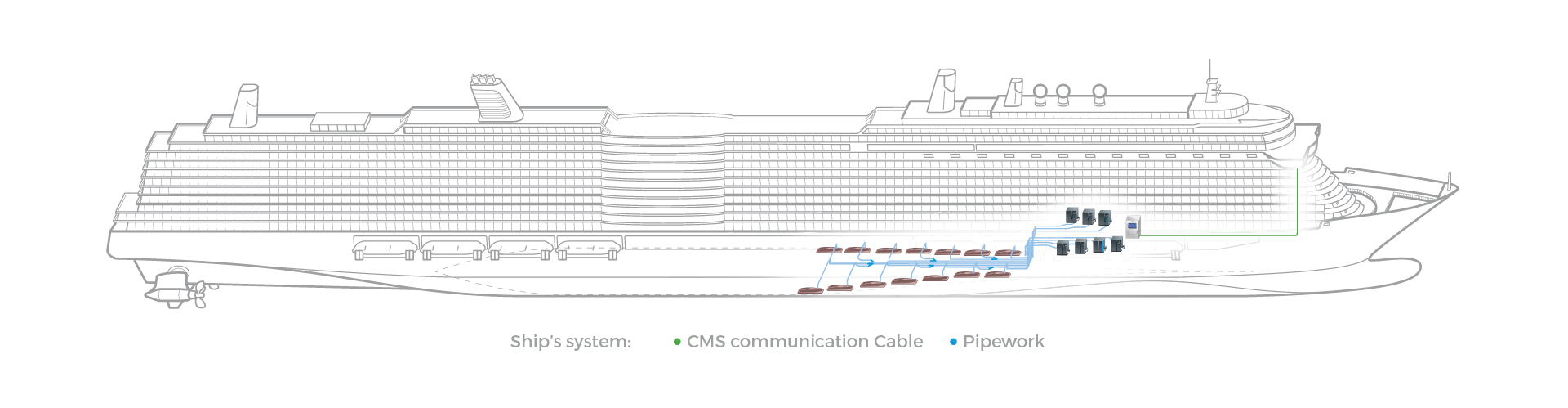

Our patented and fuel-agnostic Silverstream® System creates a uniform carpet of microbubbles that cuts frictional resistance between a ship’s hull and the water. This dramatically reduces fuel consumption and associated emissions, delivering between 5-10% proven net fuel and emissions savings, depending on vessel type. Our savings have been verified by independent third parties, including Lloyd’s Register, HSVA, the University of Southampton, Carnival and Shell.

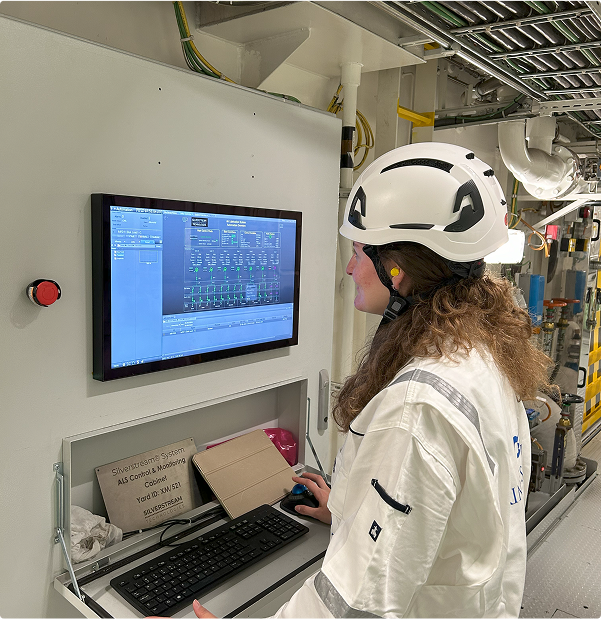

Control and Monitoring System

Control and Monitoring System

Air Compressors

Air Compressors

Air Release Units

Air Release Units

Air Balancing Module

Air Balancing Module

The air balancing module is a custom fabricated galvanised steel component for the Silverstream® System that distributes air from the compressor to both ARU branches. Flanged bosses are welded for the drain valve, level sensor and spares that are blanked to allow for troubleshooting.